Pouch packing machines are gaining popularity due to their versatility and high efficiency. Pouch packing machine offer a more efficient solution than traditional manual packing methods,

It is the perfect choice for manufacturer looking to save on costs while achieving high performance. Widely used in almost all industries, such as snack foods, powder products, liquids, sauce, granules, tea,

With pouch packing machine, producers can quickly and easily package products with minimal effort. The pouch packing machine allows for a streamlined process and offers a variety of pouch style and sizes to choose from.

In this blog we mainly focus on discussing two packaging type, the rotary premade pouch packing machine and vertical form fill seal pouch packing machine.

Introduction to pouch packing machine – (Rotary pouch packing machine)

A pouch packing machine is automatic packaging equipment that produces filled and sealed premade style bags at high speeds.

The process begins by gripping a pre-formed pouch, then filling it with the product before sealing it shut. The bag will move from one station to another in a circular layout.

The eight station rotary pouch packing machine is the most commonly used configuration. Additionally, pouch machines can come in single-lane and two-lane variations. During each station of the pouch packing process, different tasks are completed as the pouch moves around;

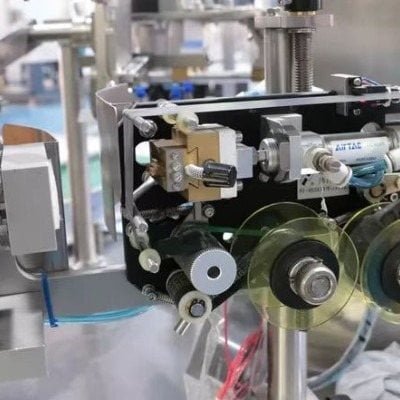

How the rotary premade pouch packing machine works

1. Pouch Loading

The pouch packing machine requires preformed pouch bags placed into the magazine at its front side by an operator. It can max hole 200-300 pre made pouches depending on the pouch style and thickness.

The pouch bags can be conveyed automatically through a feeding roller onto the machine for automatic pouch feeding.The pouch packing machine is applicable for various style of pre made bags, such as stand up pouches, three side seal pouches,

2. Pouch coding

Pouch packaging machine can come equipped with optional printing or embossing capabilities. This makes it possible to place date/lot codes onto pre made pouches through thermal or inkjet printing or by etching raised codes into the pouch seal. This is a helpful feature for product tracking and traceability.

3. Pouch opening

The pouch packing machine is equipped with a pouch opening mechanism that helps to open the pouch before filling it. Depending on the pouch, either a vacuum suction cup can be used to open the lower part of the pouch or, if it has a zipper closure, special opening jaws can be employed to open the top side of the pouch.

Additionally, the pouch can be inflated with air using an air blower to create a larger pouch for filling. This pouch opening mechanism ensures that preformed pouches are successfully opened before filling with the product.

4. Pouch filling

The product is filled into each pouch by filling machines.

A multi-head scale, linear scale, cup filler for chips granule products . An auger filler used for powder items. For liquid, a liquid filler with a nozzle pumps them into the pouch.

The filling machines ensures that the right amount of product is filled in each pouch.

5. Filling & Option

A second filling station can be included for filling products containing solid and liquid products.

Or it can be as an optional station. To maintain freshness and keep oxygen out of the pouch, a modified atmosphere packaging (MAP) process is used. This involves using a gas blast, such as nitrogen, to flush out oxygen before pouching.

Dust collection systems are also available at pouch packaging machine for powder products that produce dust or mess to capture airborne particles.

6. Product Settling & Sealing

Sometimes the contents of a pouch need to settle at the bottom before they can be adequately sealed. This station helps achieve this by gently shaking the pouch.

7. Pouch Sealing & Options

The pouch packing machine’s deflator components are used to remove any residual air from the pouch before pouch sealing. This ensures that the pouch contents remain fresh and secure for extended periods. The pouch is then sealed with heat, depending on the type of material being sealed.

8. Pouch discharge

Once complete, the bag is discharged from the machine onto a conveyor belt for further processing, such as being weighed by check weigher, metal inspected with an x-ray, or put in individual boxes or cartons by the robot. From there, the pouch can be sent to its final destination.

The pouch packing machine is designed to give consistent and reliable operation over extended periods while providing maximum accuracy and efficiency. The pouch is securely sealed and ready for distribution with minimal effort from the user.

Introduction to vertical form fill seal pouch packaging machine – (referred to vffs machine)

The vffs pouch packing machine, a vertical form fill seal pouch packing machine (VFFS), is a versatile and affordable packaging solution for various products. Liquid- sauce, shampoo, powder etc

The pouch packing machine processes and packages goods at high speed with great accuracy and efficiency.

As the name suggests, it forms the pouch out of flat film material, fills it with the product, seals it, and cuts it off at the required length to create a pouch-packed product.

1. Film Unwinding

A pouch packing machine utilizes a single sheet of film material wound around a core, commonly called roll stock. This packaging material includes polyethylene, laminated film, foil, and paper. The entire length of the film is known as the film web.

The roll of the film must be placed on a spindle assembly assembled at the rear end of the pouch packing machine. Once loaded, the pouch packing machine will unwind and transport the film for further processing.

2. Film Tension control

In pouch packaging machine, the film is unwound from a roll and passes over a dancer arm, a weighted pivot arm installed at the back of the machine.

The arm includes various rollers and works to keep the film under tension while it moves to avoid unwanted material shifting. This ensures that pouch packaging machine operate optimally.

3. Optional Printer

The pouch packing machine also includes an optional printing machine, which is added after the dancer.

This printer may be of a thermal or inkjet type and allows various dates/codes to be imprinted onto the film as needed.

Additionally, it can add registration marks, graphics, or logos to the film itself.

4..Film Tracking and Positioning

The pouch packing machine is equipped with a film tracking and positioning system to ensure that the packaging process is accurate.

After passing through the printer, a registration photo-eye detects the registration mark printed on the film. This photo-eye then controls the pull-down belts connected to the forming tube to stay aligned correctly for cutting in the right spot.

Pouch packaging machine can guarantee accurate packaging operation by tracking and positioning the film.

5. Pouch Forming

The pouch packing machine utilizes a forming tube assembly to form the pouch. As the film passes through the collar of the forming tube, it is folded around it so that the two outer edges overlap to create a film length. This marks the start of pouch formation.

6. Pouch Filling and Sealing

Depending on the products, the pouch will be filled with products by multi head scale, linear scale, or liquid filler. The horizontal sealing of the pouch packing machine will seal the bag.

Pouch packaging machines benefits

1. Easy to use and maintain:

Pouch packaging machines are designed for easy handling and maintenance. With minimal training, operators can quickly become proficient in pouch packing machine operation.

2. High-speed production:

Pouch packaging machine have a high automation grade, which ensures that large volumes of products can be packaged with little effort. The automatic filling packing sealing process also minimizes production time, helping businesses stay ahead of the competition.

4. High accuracy

The pouch packing machine is integrated with precise filling machine to provide the highest level of accuracy in industrial operations.

The filling packing sealing process is monitored for consistency and accuracy, ensuring that pouches are filled with precise doses of product each time. This helps to reduce wastage and maintain a consistent quality of packaged products.

3. Cost-effective:

Pouch packaging machines are a cost-effective packaging solution for businesses looking to save money on production costs. The minimal pouching times and minimal waste materials help reduce overall costs associated with product packaging.

4. Versatility:

Pouch packaging machine can package various products, from liquids and powders to solid objects into various pouches, such as stand up pouches, sachet pouch etc. The pouching machine’s ability to handle different pouch sizes makes it ideal for businesses with diverse packaging requirements.

5. Hygiene:

Pouch packaging machines are designed to provide a clean and sanitary packaging process. The pouching machine is equipped with features such as automatic filling, pouch packing, and pouch sealing, which help reduce the risk of contamination from manual handling.

6. Efficiency:

Pouch packaging machines are designed with built-in safety features that reduce the risk of product spoilage or damage. The machines also help automate pouching processes, which can significantly increase efficiency and reduce the amount of manual labor required.

These pouch packing machine benefits make them an ideal option for manufacturer looking to streamline their packaging operations. With their easy-to-use design, high pouching speeds, and cost-saving capabilities, pouch packaging machines can help enterprises to reduce their production costs while still maintaining high levels of quality.

Pouch packing machine Conclusion

Pouch packaging machines offer a highly efficient and cost-effective solution for packaging operations. With their high pouching speeds, easy-to-use design, and space-saving capabilities, businesses can increase efficiency, reduce cost, and improve pouching quality by utilizing pouch packaging machines.

How do you choose a suitable pouch packing machine for your specific application?

There are some factors to consider when chooseing pouch packaging machines, and each pouch packing machine is designed for a particular purpose.

The size of the pouch, the speed at which you need to operate it, the type of material being filled, and other considerations all factor into choosing the suitable pouch packing machine for your needs.

Contact Packwaytechno to discuss pouch packing machines for your specific application and find the pouch packing machine that best suits your requirements.