Suppose you are planning to purchase new packaging machine to automate your packaging process. Maybe you have already contacted packaging machine suppliers from different countries and know some basic details of packaging machines in the market.

There are a few questions you may have.

What’s the main packaging machine in the market?

Bags packaging machines cover two categories on the market based on the bag forming methods.

The first type is film roll-making bags. This bag is made, filled, and sealed by Vertical Packaging Machine. It is also named a Vertical Form Fill Seal Machine (VFFS). The VFFS packaging machine can automatically finish the process of making bags, filling products, sealing bags, and cutting. ;

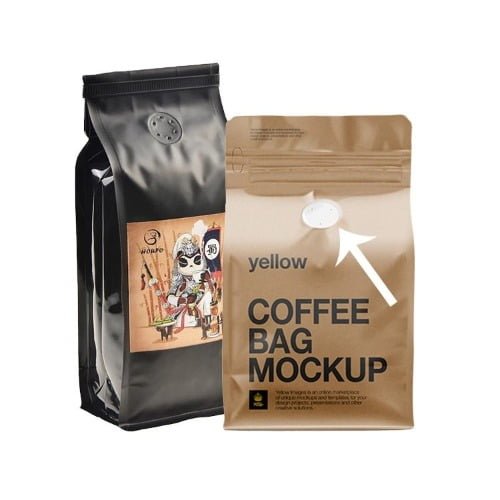

The other bag-forming method is premade bags, meaning you must buy preformed bags from the bag supplier in advance. The premade bag packaging machine will handle the rest, giving bags, opening bags, filling bags, sealing bags, and Output.

Which machine suits your need?

If you’re unsure which packaging machine is suitable for you, we may get some tips for you, please spend a few minutes reading this article carefully before making a choice!

Ask yourself, below are four questions before you make the decision:

What bag style and size do you want to handle?

The VFFS packaging machine focuses on making and sealing pillow bags, three-sided sealing bags, 4-side sealing bags, gusset bags, and block bottom bags.

Suppose you need to handle one of the above bag styles and just with several different bag sizes. No doubt VFFS machine will be a better option for each bag with a high production capacity.

The premade bag packaging machine handles different preform bags, stand-up pouches, zipper pouches, and others.

So if you have many different pouch sizes, styles, shapes, and each type with relatively low quantity to handle each day, you may need to change the bags several times on the same day. In this case, Prefer Premade bag packaging machine will be better.

Using premade pouch packaging machine will cause less downtime because the premade bag packaging machine will be much easier to adjust bag style and size when changing. Not like the VFFS machine, you have to shift forming tube and re-install the film from time to time.

What’s your budget?

Overall, The VFFS Packaging machine and the Premade bag packaging machine could share the same feeding and dosing systems series. So the feeding machine and dosing machine costs will have no significant difference. The central cost gap comes from the primary packaging machine.

For the same size bag and bag capacity project, the Premade bag packaging machine could cost two times or more than the Vertical packaging machine.

So if you want to prefer a premade bag packaging machine, you’ll need to prepare an investment for a higher-value machine.

However, the Vertical Form Film Seal machine could save you money.

What’s the waste rate of packaging material?

You can easily judge how the finished bags formed on the packing machine.

On the Vertical Form Fill Seal (VFFS) Packaging machine, you need to put the film on the packing machinery and test them on your own. It’s not complicated, and the raw material will come as big film rolls. Unit cost will be lower. But during the testing process, you may need to waste a higher rate of material because once you start running the machine, you’ll need to use packaging film, and they are not recycled used during the test. Once you are familiar with the packaging equipment, this waste rate can minimize.

The bag manufacturer produces the bags used on the premade bag packaging machine; the bag supplier will handle the raw material waste, so you all get perfect premade bags. Unit cost for the load may be higher, but it can be straightforward to fit onto the machine. And during the packing equipment setup, test it. You can use just a few bags to recycle used ones until testing finished. It’s with higher unit cost but a shallow waste rate.

What speed and Output will you need?

Generally speaking, VFFS packaging machines can reach higher speeds for the same bag capacity. The Vertical Packaging machine may handle simpler and more commonly used bag styles. Also, this makes it more capable of faster speed and enormous volume than premade-bag packaging machines.

So if high speed is your most important factor to consider, the VFFS machine can take you a lot further.

How simple is it to operate the machine?

When using the VFFS packaging machine, you will be the one to install the film and create your bags with the packaging machine. So you or your engineer will need to learn how to set up and install the film-wearing process, and if you want one packaging machine to handle different bag sizes, you’ll also need to know how to change the bag former. Not complicated, but I still need some training.

When using a Premade bag packaging machine, things will become even more manageable, and the premade bags will be delivered directly from bag suppliers to your factory. So nothing much you need to do by yourself. It’s a simple operating process, and an entry-level worker will be able to operate it.

In a word, it’s not possible to find perfect one-machine-fits-all products and bags.

Other factors not mentioned should also be taken into consideration. Some of them may be unique to your project: Like your market environment, present and future, exceptional consumer group: your local labor cost, or the current workers’ technical abilities.

Looking for an efficient packaging machine to automate your packaging process? Please contact Packwaytechno professional engineering team for a free consultant and make a detailed plan base on your case.