Stick Pack Packaging Machine Overview

A stick pack machine is a type of packaging machine widely used in various industries for powder and liquid products. It is an ideal solution for packaging drink mixes, pharmaceutical powders, sugar, salt, coffee, granules, food, and dairy products.

With their compact and convenient format, stick packs have become popular among customers.

Film Movement and Unrolling:

In the first stage of the stick pack machine’s operation, a roll of heat-sealable film is fed into the machine. The film is then transported and unwound, ready to be used in packaging.

This step is critical to ensure a continuous film supply for the packaging process. Rollers hold the film in place and control its tension and movement, and the unwinding speed can be adjusted according to the product’s packaging requirements.

Optional Printing Process:

This stage is optional, but if included, it allows for printing important information such as product branding, batch codes, and other details directly onto the film.

This is usually done through a high-resolution thermal transfer or inkjet printing system. This step helps ensure that the product is labeled correctly and meets regulatory requirements.

Film Stabilization:

After the film is unwound, it must be kept under tension to maintain stability during the cutting and packaging process. The stick pack machine has a mechanism to maintain the tension, such as tension rollers or a dancer bar. Proper tension is crucial to ensure that the film is cut and folded correctly and that the product is appropriately packaged.

Cutting Film into Sticks:

The machine then cuts the film into each stick pack’s desired size and shape using precision cutting blades or punches. The cutting process is carefully controlled to ensure the sticks are the correct size and shape and have clean and smooth edges, which is essential for easy dispensing.

Creating Stick Pack Packages:

The machine folds the film over to create the stick pack shape and seals the edges to create a pouch for the product. The sealing process is typically done using a heat sealing mechanism, which melts the film together to create a tight and secure seal. The stick packs are automatically collected and stacked, ready for the following process stage.

Product Filling and Heat Sealing:

The product is then dispensed into the pouch, and the machine seals the top to secure the product inside. The filling process can vary depending on the viscosity and consistency of the product and can be done using an auger filler, for example. The machine is calibrated to ensure that the correct amount of product is dispensed into each pouch, and the heat sealing process is controlled to ensure a tight and secure seal.

Completed Stick Packs Output:

The final stage of the stick pack machine’s operation is the output of the completed stick packs. The stick packs are collected, stacked, and packaged into boxes or cartons for shipping. The stick packs are inspected to ensure they are packaged and labeled correctly, ensuring customers receive a high-quality product.

Advantages of Stick Pack Machines:

Versatile Packaging:

Stick pack machines can package various products, including liquids, powders, granules, coffee, tea, drink mixes, and even non-free flowing powders. This makes it a suitable solution for various industries, including food, pharmaceuticals, and cosmetics.

Convenient and User-Friendly:

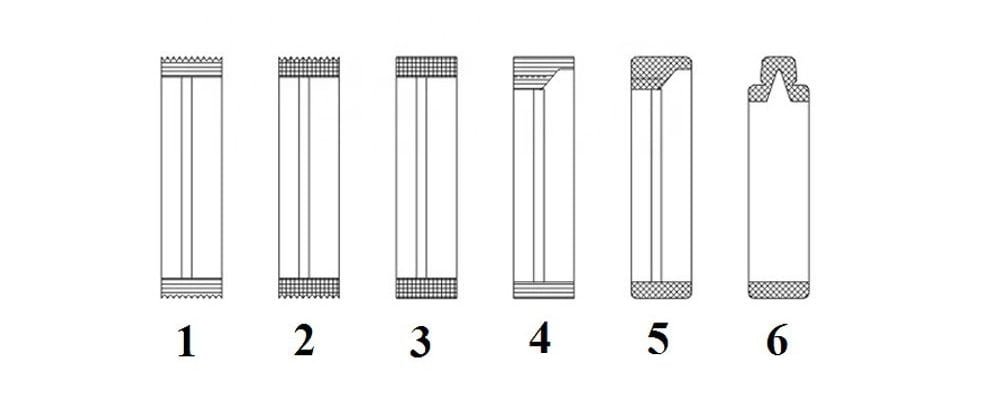

Stick pack machines are convenient for customers, as they can produce different shapes and sizes of packaging and be customized to meet specific packaging demands. With the option for multiple filling machines and a variety of seal patterns, stick packs are a versatile packaging solution.

Reliable Packaging:

Stick pack machines are designed to reliably package products, providing a secure seal and tear notch for easy opening. Stick packs offer a stable and secure packaging solution with the option for a three-side seal, making it ideal for liquid and dairy products, like olive oil, ketchup, and more.

Efficient Production:

Stick pack machines are designed for high-speed production, making them an ideal solution for businesses with high demand. With the option for multi-lane stick pack packaging, production can be ramped up to meet growing customer demands.

Cost-Effective:

Stick pack machines are an entry-level packaging solution affordable for businesses of all sizes, making it the right choice for companies looking to upgrade their packaging systems. The cost-effective nature of stick pack machines makes them a suitable solution for businesses looking to add a new product line.

Conclusion

Stick pack machines have emerged as one of the best solutions to meet the production demands of a wide range of industries.

Their multi-lane capability and ability to produce stick packs in different forms have made them a suitable choice for manufacturers looking for an efficient and reliable packaging solution.