A pouch packing machine is an automated packaging equipment that packages various products, such as food, beverages, and other consumer goods, into pouches.

Pouch packaging machine automatically fill, seal, and pack the product into a pouch. The process typically involves feeding the product into the machine, where it is weighed and measured, and then filling the pouch with the appropriate amount of product. The pouch is then sealed, and the finished product is discharged from the machine.

Pouch packaging machines come in a variety of sizes and configurations and can be designed to handle a wide range of products and packaging materials. Some standard features include automatic weighing and filling systems, multiple filling and sealing options, and the ability to package products in various pouch sizes and shapes.

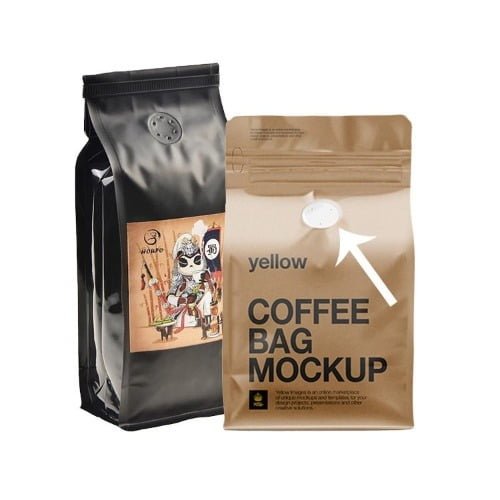

Vertical form fill seal pouch packing machine VS premade pouch packing machine

Vertical form fill seal (VFFS) pouch packaging machines and premade pouch packing machines are two different automated packaging equipment used to package products into pouches or bags. Here are some differences between the two pouch packing machines:

- Packaging process: VFFS pouch packing machine produce the pouch material and form the pouch directly from a roll of flexible packaging material. On the other hand, Premade pouch packaging machine use pre-made bags fed into the machine.

- Packaging speed: VFFS pouch packing machines are generally faster than premade pouch packing machines, as they can produce and fill the pouch material in a single continuous process. Premade pouch packing machines, on the other hand, require additional time to feed the pre-made pouches into the machine.

- Packaging material: VFFS pouch packing machines can use a wide range of flexible packaging materials, such as film, foil, and paper. Premade pouch packing machines, on the other hand, are limited to the materials used to make the pre-made pouches.

- Packaging options: VFFS pouch packing machines offer more flexibility in pouch size and shape, as the pouch is produced directly from the roll stock material. Premade pouch packing machines are limited to the dimensions and conditions of the available pre-made pouches.

- Cost: Premade pouch packing machines are generally more expensive than vffs pouch packing machines, as they are more complex and have more features. Vffs pouch packing machines are often more straightforward and more affordable.

Ultimately, deciding between a VFFS pouch and a premade pouch packing machine will depend on your specific packaging needs and budget. Factors such as production volume, packaging material, and pouch size and shape will all play a role in determining the most suitable option for your application.

Pouch style on VFFS pouch packing machine AND premade pouch packing machine

Vertical form fill seal (VFFS) pouch packing machines are automated packaging equipment that packages products into pouches or bags. VFFS machines produce the pouch material and form the pouch directly from a roll of flexible packaging material. Here is a brief description of the pouch styles.

- Pillow bag: A pillow bag is a type of pouch shaped like a pillow with a flat bottom and two sealed sides. It is often used for packaging dry goods such as snacks, cereals, and pet food.

- Gusset bag: A gusset bag is a type of pouch with a gusset on the bottom, allowing it to stand upright when filled. It is often used for packaging products such as coffee, tea, and pet food.

- Block bottom bag: A block bottom bag is a type of pouch with a flat bottom and a stand-up gusset on the sides. It is often used for packaging dry goods such as flour, sugar, and rice.

Premade pouch packing machines are automated packaging equipment to package products into pre-made pouches or bags. Here is a brief description of the pouch styles:

- Stand up pouch: Stand up pouches have a flat bottom and can stand upright on a shelf or counter. It is often used for packaging dry goods such as snacks, cereals, and pet food.

- Flat pouch: A flat pouch is a type of pouch that does not have a stand-up bottom. It is often used for packaging liquids, powders, and granular products.

- Zipper pouch: A zipper pouch is a type of pouch that has a zip closure, which allows the product to be sealed and opened repeatedly. It is often used for packaging dry goods such as snacks, cereals, and pet food.

- Block bottom pouch: A block bottom pouch is a type of pouch that has a flat bottom and a stand-up gusset on the sides. It is often used for packaging dry goods such as flour, sugar, and rice.

Remember that the specific pouch styles produced by a particular VFFS or premade pouch packing machine will depend on the specific model and its capabilities.

Pouch packaging machines benefits

There are several benefits to using a pouch packing machine for packaging products:

- Increased efficiency: Pouch packing machines are highly automated and can package products much faster than manual methods, which helps to increase productivity and reduce labor costs.

- Improved accuracy: Pouch packing machines are equipped with sensors and other technology that help to ensure accurate filling and sealing of the pouches. This helps to reduce waste and improve the overall quality of the packaged product.

- Enhanced flexibility: Pouch packing machines can be configured to package a wide variety of products in different pouch sizes and shapes, making them suitable for use in various industries and applications.

- Reduced packaging material costs: Pouch packing machines can often use less packaging material than other packaging equipment, which can help reduce material costs.

- Improved product shelf life: Pouch packing machines can be equipped with features such as modified atmosphere packaging (MAP) and vacuum sealing, which can help extend the product’s shelf life.

- Increased sustainability: Pouch packing machines can help reduce waste and packaging material consumption, contributing to a more sustainable and environmentally-friendly packaging process.

How to choose a suitable pouch packing sealing machine

There are several factors to consider when choosing a suitable pouch filling packing machine for your packaging needs:

- Product type: The product you are packaging will play a significant role in determining the appropriate pouch packing machine. You will need to consider the product’s size, shape, and other characteristics, as well as any special handling requirements.

- Packaging material: Different pouch packing machines are designed to work with different packaging materials. You will need to choose a machine compatible with the material you plan to use.

- Production volume: The production volume of your packaging process will determine the size and capacity of the pouch packing machine you need. Make sure to choose a machine that can handle the volume of product you need to package.

- Packaging format: Consider the size and shape of the pouch you need to package your product. Make sure to choose a pouch packing machine capable of producing the desired packaging format.

- Budget: Pouch packing machines come at different prices, from basic manual machines to fully automated systems. Determine your budget and choose a machine that fits your needs and budget constraints.

- Reputation: Choose a reputable pouch packing machine manufacturer or supplier with a track record of producing reliable equipment. Consider purchasing from a company that offers good customer service and technical support.

- Maintenance and service: Consider the maintenance and service needs of the pouch packing machine you are considering. Choose a machine that is easy to maintain and has a good track record for reliability.

How to operate pouch packing machine

Pouch packaging machines are automated systems that package various products, such as food, beverages, and other consumer goods, into pouches or bags. These machines can be operated in a variety of ways, depending on the specific model and the type of product being packaged. Here are some general steps that you can follow to operate a pouch packing machine:

- Prepare the product: Before starting the pouch packing machine, make sure that the product is ready to be packaged. This may involve weighing, measuring, or preparing the product according to the machine’s specifications.

- Load the pouch material: Many pouch packaging machines use roll stock material, a continuous roll of flexible packaging material fed into the machine. You need to open the machine and thread the rolling stock through the appropriate guides and rollers to load the pouch material.

- Set up the machine: Depending on the specific model of pouch packing machine, you may need to set up various parameters and settings, such as the size and shape of the pouch, the type of sealing, and the filling rate. Consult the machine’s manual or the manufacturer’s instructions to determine the correct settings for your particular machine.

- Start the machine: Once the machine is correctly set up and the product is ready to be packaged, you can start the machine by pressing the appropriate button or switch. The machine will then automatically fill, seal, and package the product into pouches.

- Monitor the machine: As the machine operates, you should watch the process to ensure everything runs smoothly. If you notice any issues, such as jams or faulty seals, you may need to stop the machine and troubleshoot the problem.

- Maintain and clean the machine: Pouch packing machines require regular maintenance and cleaning to ensure they continue operating efficiently. This may involve lubricating moving parts, cleaning equipment, and replacing worn or damaged components. Consult the machine’s manual or the manufacturer’s instructions for specific maintenance and cleaning procedures.

Conclusion

Pouch packing machines are a vital part of the packaging business, providing an efficient and cost-effective solution for filling and sealing pouches with a variety of products.

From food and beverages to consumer goods, these machines are capable of handling a range of pouch styles and are essential for preserving and protecting products for consumers.

When selecting a pouch packing machine, it is important to consider the type of product being packaged, the volume and speed of production, and the desired pouch style.

Proper operation and maintenance of the machine are also crucial for ensuring reliable performance and high-quality packaging.

In conclusion, pouch packing machine play a vital role in the packaging industry, helping to protect and preserve products for consumers.