As a business owner or packaging professional, you always look for effective ways to improve your products’ quality and shelf life.

One option to consider is Modified Atmosphere Packaging (MAP).

This post will explore the benefits of using MAP for packaging and the factors to consider when determining if it is suitable for your business. We will also discuss the cost and packaging machines requirements of implementing MAP and the compatibility of MAP with your products and packaging materials.

By the end of this blog, you will have a better understanding of the potential benefits and considerations of using MAP in your packaging line.

Introduction to Modified Atmosphere Packaging (MAP)

Definition of MAP and how it works

Modified Atmosphere Packaging controls the atmosphere within a package to extend the shelf life and preserve the quality of perishable food and beverage products.

According to the Food and Drug Administration (FDA), MAP involves modifying the composition of gases in the package or using a specific type of film to create the desired atmosphere.

There are two types of MAP: active and passive. Active MAP involves replacing the package’s gases with a specific mixture. In contrast, passive MAP relies on the natural respiration of the product and the diffusion of gases through the film to create the desired atmosphere.

MAP’s goal is to reduce oxidation and spoilage and increase the shelf life of the packaged product.

Types of Modified Atmosphere Packaging (MAP)

Several types of map food packaging are commonly used in the food industry. These include:

Nitrogen flushing:

Nitrogen gas flushing is a type of MAP that involves replacing the air in the package with nitrogen gas before sealing it.

Nitrogen is an inert gas that does not react with food, making it a practical choice for preserving the quality and extending shelf life for food products.

Nitrogen flushing can extend the shelf life of many products, including meats, dairy products, and fruits and vegetables.

One way degassing valve:

A one way degassing valve is a small plastic valve used in modified atmosphere packaging to allow gases to escape from the package but not enter. These valves are often used in packaging coffee beans and tea to allow excess carbon dioxide to escape and prevent the package from bloating.

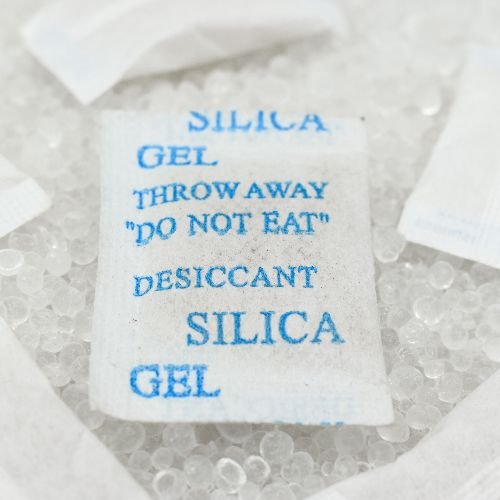

Scavenger or desiccant packs:

Scavenger or desiccant packs are small packets containing material that absorbs moisture and gases. These packs can be used in modified atmosphere packaging to absorb excess moisture and gases, which can help extend the product’s shelf life.

Barrier films:

Specific barrier packaging films are designed to block oxygen transmission and other gases. Barrier packaging films can be used in passive modified atmosphere packaging to create a modified atmosphere within the package by limiting the exchange of gases between the inside and outside of the package.

Vacuum packaging:

Vacuum packaging is modified atmosphere packaging that involves removing the air from the package before sealing it. Vacuum packaging is often used for meats, cheeses, and other products that are easily damaged by oxygen. It can ensure longer shelf life for the product by reducing the presence of oxygen and preventing the growth of bacteria.

Benefits of using MAP for food packaging

Extend shelf life for fresh products:

By altering the atmosphere inside the packaging, MAP can slow down the natural deterioration process and extend the time that the food product can be stored and sold. This is especially useful for fresh products with a short shelf life and preserving food quality, such as fresh fruits and vegetables, which can quickly spoil if not properly stored.

Preservation of quality and taste:

By slowing down the natural deterioration process, MAP can prevent the product from losing its flavor, texture, and nutritional value. This can be especially important for products sensitive to temperature and humidity changes, such as fresh fruits and vegetables.

Reduction of food wastage:

By extending the shelf life of fresh products, MAP can help reduce the amount of food thrown away due to spoilage. This not only helps to save money for the business, but it also has environmental benefits by reducing the amount of food that ends up in landfills.

Suitability of MAP for your packaging line

Factors to consider when deciding if MAP is right for your business:

When deciding if MAP is suitable for your business, there are several factors food manufacturers should consider.

These factors include the type of product being packaged, the desired shelf life of the product, the distribution and storage conditions of the product, and the cost and equipment requirements of implementing MAP.

It is essential to carefully evaluate these factors to determine if MAP is suitable and cost-effective for your business.

Cost and equipment requirements:

One of the factors to consider when deciding if MAP is right for your business is the cost and equipment requirements.

Implementing MAP may require the purchase of specialized equipment and specific packaging materials, which can add to the overall cost of the packaging process.

Food producers have to carefully evaluate the cost-benefit of MAP and consider whether the potential benefits outweigh the additional costs.

Compatibility with your products and packaging materials:

Another factor to consider when deciding if MAP is right for your business is the compatibility of MAP with your products and packaging materials.

MAP may not be suitable for all products and packaging materials, and ensuring that the selected gases and packaging materials are compatible with your products is essential.

It is very important to consider the impact of MAP on the product’s appearance, texture, and flavor.

Conclusion

In summary, Modified Atmosphere Packaging is a technique that can be used to extend the shelf life of fresh products and preserve their quality and taste.

While there are benefits to using MAP, it is crucial to carefully evaluate the suitability of MAP for your business and consider the factors that may impact its effectiveness, such as the type of product being packaged, the desired shelf life of the product, the cost and equipment requirements of implementing MAP, and the compatibility of MAP with your products and packaging materials.

Ultimately, the decision to use MAP will depend on your business’s specific needs and goals and whether the potential benefits outweigh the costs and other considerations.