Rotary Premade Pouch Packing Machine

Rotary Premade Pouch Machines In Action

Candy stand up Pouches Packing Machine

Pre made Pouches Powder Packing Machine

Pet Food Pouch Packing Machine

Semi Automatic Stand up Pouches Packing Machine

Liquid Detergent Pouch Packing Machine

Snack Stand up Pouches Packing Machine

Rotary premade pouch packing machine Systems

Packwaytechno’s Rotary Pre made Pouch Packing Machine is an excellent choice for businesses requiring a fast and efficient packing solution. It is capable of creating up to 60 pouches per minute, with pouch width ranging from 60 to 250 mm wide.

The machine also includes optional features such as gas flushing, horizontal bag feeder, automatic zipper opening device, heavy pouch support, blowing bag function, bag shaker, and code printer for extra reliability, flexibility, and efficiency.

Its design is user-friendly and easy to operate and maintain. With Packwaytechno’s pouch packing machine, businesses can be sure they are getting a dependable packing solution that meets their needs.

Rotary premade pouch packing machine main features

Rotary premade pouch packaging solution is a flexible and efficient way to package various products in different pouch styles. It can be integrated with various filling machines for different industries.

Rotary pouch packing machine features an auto-stop function for filling, preventing wasted product from being filled into unopened pouches. A no fill, no seal feature allows unopened bags to be reused.

The machine has a toolless changeover and can store up to multiple different recipes in its Human Machine Interface (HMI).

The pouch packing machine is operated via PLC control with touch screen functions. In addition, it comes with production meomory that includes gripper size, bag size, machine speed, sealing temperature and filling volume.

The pouch presence detection function prevents any pouch from being filled or sealed without pouch presence. It also has a deoxidizer feeding station, two step sealing process and cooling station for liquid products.

This pouch packing machine is equipped with a highly robust stainless steel frame and food grade contact parts that ensures its long-term efficiency and accuracy. It is suitable for a wide range of pouch packing applications.

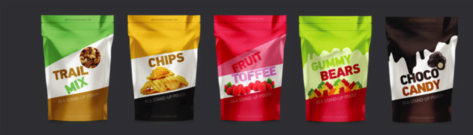

Rotary premade pouch packing machine pouch styles

Rotary Pre made Pouch Packing Machine can create premade pouch options such as stand up pouches, zipper pouch, 4 side sealing pouch, gusset pouch, and even irregular shaped pouch. The versatility of the machine helps ensure that businesses have the right pouch style to meet their needs.

stand up pouches

gussset pouch

flat bottom pouch

flat pouch

irregular shaped pouch

Rotary premade pouch packing machine Applications

Rotary premade pouch packing machine

Streamline your operations and boost output with our rotary pouch packing machine. The pouch packaging machine presents a modern, convenient look that can give your product an edge over the competition.

Packwaytechno rotary pouch packing machine consist of eight stations, enabling you to package anything from coffee and snacks to legal cannabis products.

It can easily integrate with volumetric filler, multi-head scale, auger filler, liquid pump, and cup fillers as well as infeed and outfeed conveying equipment, z bucket elevator, integrated exit conveyor etc.

As a result, this pouch packing machine provides complete pouch packaging solutions. Investing in this pouch packing machine is a great way to increase your efficiency and optimize your productivity.

What is a Rotary premade pouch packing machine?

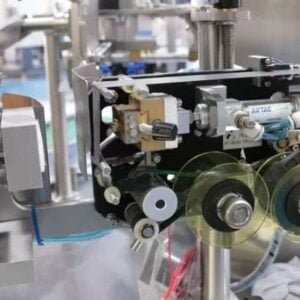

It is an automated machinery used to pick, fill and seal pre made bags. It is built with 8 individual workstations that are capable of performing the pouch packaging process in its entirety.

This includes loading the pouch, printing, pouch opening, filling and sealing it and then conveying the finished product. The rotary pouch machine is designed for high speed operation which helps make pouch packaging more efficient.

How Does a Rotary premade pouch packing machine Work?

Pouch Loading: The first step in the pouch packing process is bag loading, where the pouch is placed onto the magazine of the machine. This can be done manually or automatically depending on the model of pouch packing machine.

Pouch coding: The pouch is then gripped and held in place for further processing.Optional printing can be done at this stage, if desired. This would involve a process of inkjet printing, pad printing or hot stamping depending on pouch design.

Pouch opening: The pouch is then opened and the filling product is detected. This is usually done using a pouch detection system or pouch clamping mechanism.

Fill station: The pouch is then filled with the desired product, either by gravity filling or a pouch filling head.

Optional: After the pouch is filled, product settling or other options such as vibration may be used to ensure that the pouch is uniformly filled.

Pouch sealing station #1

Pouch sealing station #2

Pouch output: The pouch is then deflated and cooled before finally being discharged from the pouch packing machine.

Benefits of Rotary Premade Pouch Packing Machine

The pouch packing machine allows for easy switching between different bag sizes, which means you can package different products with minimal downtime. This flexibility can help increase production efficiency and reduce costs.

The user-friendly design of the machine makes it easy to learn and use efficiently. This can help reduce the need for specialized training and increase productivity

Rotary premade pouch packing machines provide fully automated production which increases efficiency and speed of the packaging process, making it possible to package large number of products in a shorter period of time.

Using a pouch packing machine reduces the amount of labor required in the production process, which can help lower labor costs and increase overall productivity.

The pouch packing machine greatly reduces waste, by reducing the amount of packaging materials needed and minimizing the amount of product that is wasted during the packaging process.

The preformed pouch design of rotary premade pouch packing machine is an attractive packaging option for many different consumer groups. This design allows for a clear view of the product inside and can help increase brand recognition and consumer appeal.

More Pouch Packaging Machine Solutions

Looking for other type packing machine? We offer other packaging solutions to meet various needs, such as vertical form fill seal machines and Multi lane Stick pack machines.

Our machine are designed to be reliable and easy to use, offering maximum output with minimal effort. Whether it be for powder products, granules, solids, liquids or sauces, we have the right machine for you.

Ask For Free Consultation

FAQ & Resources

Be sure to read the faq & resources to have better insights about the vertical form fill seal machines.

Acknowledge that these machines offer immense potential for your business and can automate many processes. The use of such a machine can save you time and money in the long run. Utilize it to its full potential.

The price of a rotary pre made pouch packing machine can vary significantly, depending on the type and size of pouch being packed.

Generally, pouch packing machines range from $20,000 to $50,000 or more.

It is typically used with various types of film material, such as polyethylene materials (PE), PET, laminate materials, paper and aluminum foil.

These films are usually laminated together for increased strength and durability, meaning that two or more layers of the film are joined together to create a stronger barrier which reduces the risk of rips and tears.

This makes pouch packing machines an ideal solution for various packaging needs.

Using a Rotary Premade Pouch Packing Machine couldn’t be easier.

All the operator needs to do is load their pouch packaging materials into magazine, make adjustments to settings such as temperature and speed according to product requirements, then hit start.

it’s that simple!

With user-friendly controls, precise settings and minimal manual operation, pouch packing machines make light work of pouch packaging.

Maintaining a Rotary Premade Pouches Packing Machine is essential for ensuring its optimal performance.

It’s crucial to inspect the seals, and drive systems regularly to check for signs of wear or damage and to adhere to the manufacturer’s recommended maintenance schedule.

Only use genuine parts from the original manufacturer if a feature needs replacing.

Additionally, it’s essential to keep the area surrounding the pouch packing machine clean and free of debris to minimize contamination risk.

Premade Pouch Packing Machine Guideline – PackwayTechno

Pouch packaging machines come in all shapes and sizes, each with features. But they all have one common goal – to package your product in

VFFS Machine VS Premade Pouch Packing Machine

VFFS Machine and Premade Pouch Packing Machine are the most popular packaging equipment used in most of industries, What are the differences between them, and how to choose the suitable style as per your packaging needs?