Quality Assurance

We are aimming

To Delivery The Best From Beginning

We are dedicated to providing you with a high-efficiency, ease-of-use, and durable packaging machine. Hence from the start, we are using high-quality materials and components for manufacturing the packaging machine by our skillful workers under clear given manufacturing standards.

Raw Material

High strength and Food grade 304 stainless steel material to provide strong structure. It is hygienic and durable.

Key Components

Our machine equipped branded electric components guarantee reliable quality. Such as Siemens PLC and Airtac air cylinder.

Strict inspection

Income material must be thoroughly inspected according to the quality control checklist before sending to our machine assembly line.

We Are Partnered With

Reliable Quality Comes From

Precise Manufacturing Parts

Poorly manufactured machines may not be found in a short period. We know how vital a durable packaging machine is to you. Hence we precisely manufacture our packaging machine, aiming to create long-term benefits for you rather than a considerable margin from a one-time deal.

Parts processing

Precise parts manufacturing ensure the machine can be assembled smoothly.

Metal plate bending

Qualified bending provides the expected strength and precision part for the manufacturing process.

Parts welding

Suitable welding supports packing machine structure and reduces broken parts risks.

Parts polishing

Polishing removes any possible sharp edge And keeps the machine operator away from injury.

We Committe To

Delivery The Best Packaging Machine By Every Small Step

Every small step matter to us, and we are grateful for you giving us the opportunity—no matter whether it is a single-unit machine OR an utterly automatic packaging line order. Our team will treat it seriously and fulfill your expectation.

Factory acceptance test

We will test your packaging machine by the requirement we agreed upon.

Including packaging speed, accuracy, sealing tightness, machine overall dimension checking, packaging label, HMI language, etc.

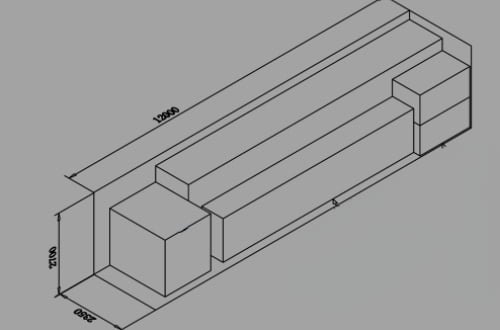

Container loading planning

Before shipment, we will provide you with a container loading layout indicating your machine model, package quantity, and packaging dimension.

We will assist you in arranging shipment booking or recommend our forwarder for your reference if needed.

Strong packaging box

All your machines will be packed with solid package boxes after getting your approval for shipment.

Our packaging cases are vital to protect your machines from being damaged. And all packaging boxes meet fumigation requirements for exporting.

Container loading for shipment

We are responsible for checking your container and ensuring it is in good condition and qualified for loading.

Container loading photos and all related info will be sent to you to trace shipment status within one day after loading.

Our Warranty

Packway manufactures all packaging machines. We are warranted to you with 13 months warranty from the date of shipment.

Warranty covered

Original defects in non-wear parts on the packaging machine.

Software issues result in a malfunction of the packaging machine.

Any damages to the packaging machine caused by a Packway engineer and technician.

Warranty not covered

Wear parts: such as belts, seals, bearings, forming sets, jaws, heaters, etc.

Any damage not caused by a Packway machine defect.

But accidents happen or not proper operation and artificial damage.

Modification of the machine without our engineer's instructions.

know how

Not sure if your parts are under warranty? Please send us an email or call our service hotline directly.

Send necessary info to check if your parts are under warranty, i.e., part number, label, order No, etc.

We suggest you use Packway origin spare part replacement to ensure running smoothly, especially critical parts.