Machine Introduction

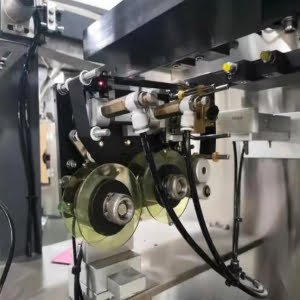

Horizontal doypack packaging machines are compact and high speed solutions often used to pack various kinds of powder in pre-made pouches.

The auger filling machine is often chosen as the upstream filing machine for the doypack system, also known as an Auger filler. This machine uses volumetric metering to fill free-flowing or non-free flowing powders, and for a fully automatic powder packing solution, the auger screw conveyor or vacuum feeder is also incorporated.

Doypack machines are commonly used in many industries such as coffee, spice, detergent and milk powder packaging. Popular pre-made pouch styles include flat pouches, zipper pouches and M-shaped pouches.

Since each product has different characteristics such as size, bulk density and flow performance, the auger screw of the auger filling machine must be customized precisely to ensure accurate filling and efficient output.

The open frame design of the auger filler allows for easy access to the machine components, making it convenient for auger screw changes and cleaning or maintenance. This helps to minimize downtime and improve efficiency.

In contrast to manual filling, an automated auger filler will provide a superior degree of precision. This is particularly important when it comes to products that are sensitive in terms of weight and quality control. Moreover, the sanitary design and construction of the machine ensures safe operation, as well as protecting product quality and integrity.

By combining an auger filler and doypack packaging machine, businesses can gain increased production speeds, improved accuracy in filling, as well as greater efficiency and a higher quality of product.

40pbm

Min

80mm W x 110 mm L

Max

260mm W x 380 mm L

| Model | WPT-160 | WPT-210 | WPT-260 |

| Speed | 5-50bag/min | 5-50bag/min | 20-50bag/min |

| Power | 2kw | 2kw | 3.5kw |

| Bag size | W:80-160mm L:110-240mm | W:110-160mm L:110-280mm | W:120-260mm L:120-380mm |

| Packaging capacity | 10-200ml | 100-1000G | 50-1000ml |

| Air consumption | 0.7m3/min | 0.7m3/min | 0.7m3/min |

| Applicable bag style | 3/4 side sealing bag paper bag,standup bag, zipper bag | 3/4 side sealing bag paper bag,standup bag, zipper bag | 3/4 side sealing bag paper bag,standup bag, zipper bag |

Address: No 7, Xiantang Industrial Ave ,Shunde, Foshan,Guangdong,China

Email: packwaymachinery@gmail.com

Don’t worry. We hate spam. Your private information will be kept confidential.