Doypack Packaging Machine

Doypack Packaging Machine In Action

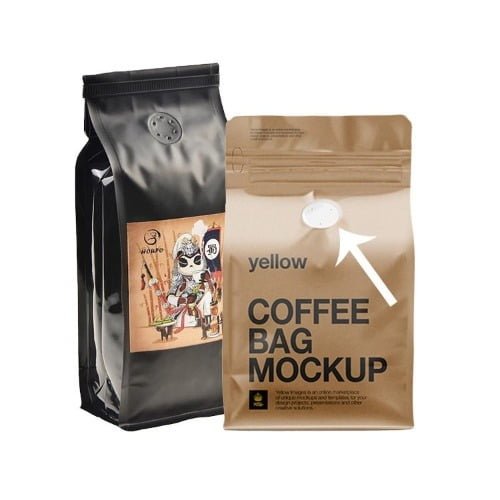

Doypack machine for coffee bean

Dry Fruit Pouch Packing machine

Pet food doypack machine

Doypack Packaging Machine

The Doypack Packaging Machine is specially designed for packing products into Doypack bag. It can craft Doypacks with zippers and other variants of the Doypack design.

Its efficient and reliable technology allows for maximum flexibility in packaging. Doypack machines are ideal for businesses that require efficient packing solutions with their dedicated and easy-to-use design.

Doypack Packaging Machine System

A Doypack Packaging Machine is quickly becoming an attractive choice for various packaging applications like pet food, coffee, cannabis, snacks, powder, pharmaceuticals products, cosmetics products, viscous products, as well as non food products .

These eye-catching pouches help set your product apart from the competition. The Doypack pouches can be filled and sealed using a Rotary Premade Pouch Packaging Machine or a horizontal pouch packing machine.

Rotary Premade Pouch Packing Machines

The premade pouch packing machine is the perfect solution if you’re looking for a reliable and efficient Doypack Packaging Machine.

Packwaytechno team has designed it to provide an optimal price/performance ratio when filling and sealing Doypaks. This rotary premade pouch machine offers robust construction, so you’ll get the best Doypacks on the market.

The rotary premade pouch machine is made from the highest quality materials and the most reliable components to ensure maximum reliability and durability.

It was built with eight working stations with open frame structure, which enable the operator quick access for operation and maintenance. It can fill and pack pre-made pouches format ranging from 160 to 300 mm in width, with a maximum speed of 60 bag per minute.

This ensures that businesses can fill their products quickly and efficiently, maximizing productivity and cutting costs.

Horizontal doypack machine

Packwaytechno’s Horizontal Doypack Machine is a mid-high speed solution to meet various applications and requirements. The Doypack Machine features a simplified structure that occupies less space and makes it easy to maintain. The intuitive touchscreen provide ease of use operation.

In addition, this machine can be integrated with various filling machines, enabling it to package liquids, powders, and granules with a maximum speed of 40 pouches per minute.

PLC-based touchscreen control systems provide accurate and swift responses for production.

It is a cost-effective solution that offer excellent flexibility and stability for Doypack packaging.

Benefits of Doypack Packaging

Eye-catching

Doypacks feature a rigid structure and stand-up properties, offering maximum visibility and marketability.

Stand unassisted

Doypacks come with a bottom gusset, allowing them to stand up without any support.

Fantastic convenience

Doypacks offer various features such as corner spouts, reclosable zippers, and shaped profiles. These features further increase the usability of Doypack products.

Perfect for branding

The large surface area of Doypack packaging makes it perfect for displaying logos, product information, or promotional messaging.

Great adaptability

Doypacks are customizable and can be made from a variety of materials such as paper, aluminum foil, PE etc

How to choose a doypack packaging machine

Doypak machines can accommodate different products, such as liquids, powders, and granules. You may need to integrate specific filling machines to ensure proper filling and sealing processes.

A rotary premade pouch packing machine can produce up to 60 pouches per minute, while a horizontal doypack machine can produce 40 pouches per minute. Choose a Doypack Packaging Machine with a suitable capacity for your production output to achieve efficiency and speeds.

If your products need to be packed into various sizes of pouch, it is best to inform the supplier so they can recommend an appropriate model that can accommodate all SKUs. This way, you will only have to purchase one machine. You won’t need to buy multiple machines for different products.

Consider if your project requires extra capabilities such as a Horizontal Bag feeder, Date coding machine, Zipper enclosure device, spout etc.

Ensure This doypack packaging machine is designed to be easily customized to fit the exact requirements of your project. and all features are correctly implemented in order.

FAQ & Resources

Investing in a doypack packaging machine can be an effective way to boost efficiency and minimize labor costs.To ensure you get a suitable pouch packing machine, it is essential to research and become well-versed in its features and capabilities.

Make sure to read up on any relevant questions or resources related to the machine to understand its full potential and how it can improve your operations.

Doypack machines are designed to package products in pre-prepared pouches, ready for distribution or sale.

This type of packaging is ideal for a range of businesses as it enables them to keep up with customer demand while creating an attractive product that accurately reflects their brand.

In 1962, Louis Doyen, managing director from the packaging factory in St. Germain au Mont d’Or, France, invented the Doypack.

He sought to create an effective way of packing and preserving fruit juices and olives for transport.

The Doypack name is derived from the surname of its inventor. The bag design has been successfully used and is still popular today.

Doypacks come in various materials, such as aluminum, kraft paper, and transparent or eco-friendly plastic.

The type of material being used depends on the product being stored inside. Many different styles are available for consumers to choose from.

Flexible pouches are commonplace on store shelves worldwide, offering a versatile solution for packaging an array of items, from snacks and foodstuffs to liquids.

These pouches have become especially popular over recent years as an ideal way to package food products.

What does the pouch packing machine cost?

When working with customers in flexible packaging, pouch packing machine cost often comes up in conversation. Many newcomers to the industry are curious about what

VFFS Machine VS Premade Pouch Packing Machine

VFFS Machine and Premade Pouch Packing Machine are the most popular packaging equipment used in most of industries, What are the differences between them, and how to choose the suitable style as per your packaging needs?