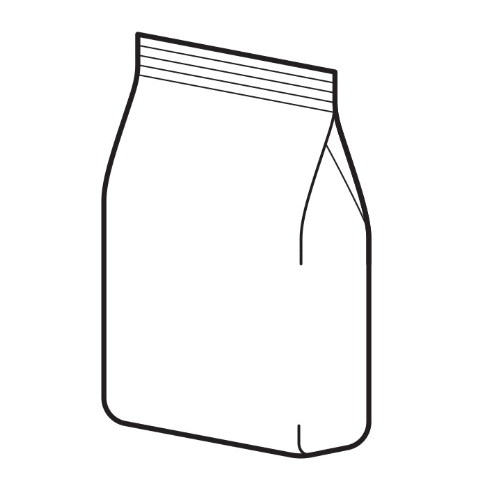

Block Bottom Bag

A block bottom bag is a type of self-standing gable-top package. It has an extra feature: the wide side gussets that provide strength and stability to its design.

The structure consists of a top and bottom seal and supports itself due to the wide side gussets defining it. This style of bag is sometimes known as the Side Gusset Bag.

The design of the block bottom bag can be tailored to fit the requirements of a product and its associated brand.

It is possible to include different types of hole punches for display purposes and additional features, such as zipper and perforations that offer easy opening and reclosure capabilities.

These features make the bag highly versatile and suitable for various uses.

Block Bottom Bag Benefits

Excellent stability:

Block bottom bags have a flat and stable base that prevents the bag from tipping over when placed on the shelf or other surfaces. This makes it easier to organize products and helps keep them looking neat as like stand up pouch.

Large filling volume:

The flat base of block bottom bags provides more space for product filling. This means that the bag can hold a larger quantity of goods than other types of packaging, making them great for bulk items or large products.

Easy to stack:

Block bottom bags are more straightforward than other bag styles due to their square shape and flat base. This makes. This makes them great for storing and shipping products, as they can be stacked neatly and securely.

Suitable for branding:

Block bottom bags offer excellent branding potential, as they can be printed with messaging on the front, back, and side panels. This helps them stand out on shelves, drawing attention to the product inside.

Block Bottom Bag material and options

Block Bottom Bags are an ideal solution for packing coffee, nuts, candy, and beans in a visually appealing way. These bags typically feature layers of Low-Density Polyethylene (LDPE), Polypropylene (BOPP), or Polyethylene Terephthalate (PET), which offers flexibility and durability.

A combination of materials, such as Aluminum with PET and PP, can further increase the pouch’s strength. Two to three layers of LDPE are added during production to ensure it is flexible and provides a secure seal.

Block bottom Packaging includes flexible options as below

- Tin tie

- One-way degassing valve

- Reclosable zipper

- Easy tear notch

Block Bottom Bag sample

Block Bottom Bag packaging machines

The Vertical Form-Fill-Seal (VFFS) Machine is an excellent choice for creating rolls film type block bottom bags. It can be used in conjunction with a variety of filling machines like the Multi-Head Weigher, linear weigher, volumetric cup filler, and auger filler to fill the bags with a range of products such as coffee, nuts and chocolates, fruits and vegetables, ready-to-eat meals, soups and sauces, snack foods and trail mixes, pet foods and more.

The premade pouch packing machine is an excellent option for those who wish to use pre-made style block bottom bags. The rotary premade pouch packing machine can reach speeds of up to 60 pouches per minute, and the horizontal doypack machine can reach 40 pouches per minute.

All these machines are flexible to featured necessary options, such as one way valve, easy tear notch etc.

Block Bottom Bag machines video

Pet food packaging machine

Snack vffs machine

Pet food vffs packaging machine